Essential Care and Maintenance for Harvesting Equipment

Date: 24/03/2023

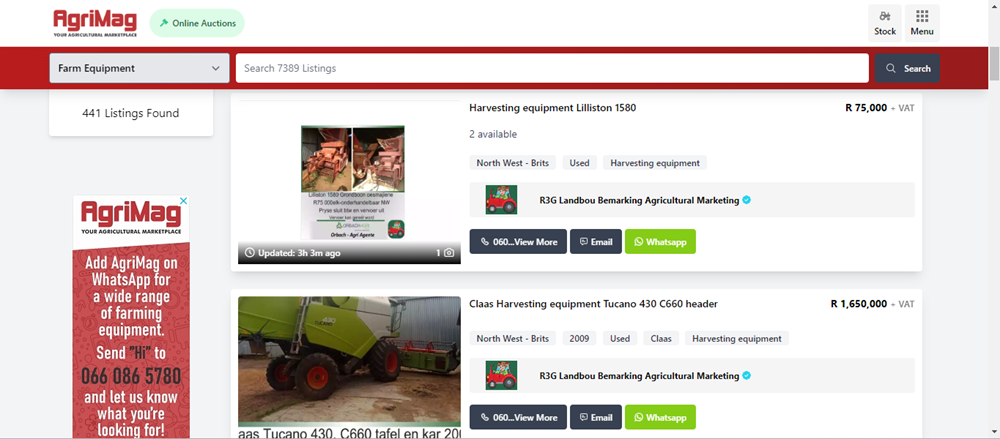

Proper maintenance for harvesting equipment is crucial for ensuring efficient and effective agricultural operations, especially in South Africa's diverse farming landscape. Regular upkeep not only extends the lifespan of your machinery but also minimises downtime and repair costs. In this article, we will discuss essential care and maintenance practices for your harvesting equipment, helping you maintain peak performance throughout the harvesting season. Receive alerts on AgriMag whenever a new listing with the following details is added.

Understanding the Importance of Maintenance

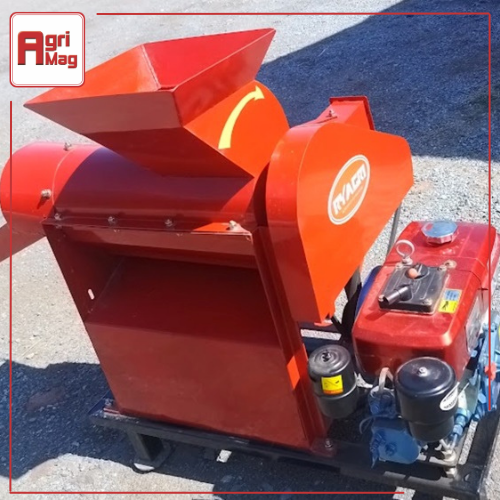

Harvesting equipment, such as combines, balers, and tractors, plays a vital role in modern agriculture. These machines are subjected to heavy use and harsh conditions, making routine maintenance essential to avoid breakdowns and ensure smooth operations. Proper maintenance helps in:

- Increasing Equipment Longevity: Regular checks and timely repairs prevent minor issues from becoming major problems, extending the lifespan of your machinery.

- Enhancing Efficiency: Well-maintained equipment operates more efficiently, saving time and reducing fuel consumption.

- Ensuring Safety: Regular maintenance checks help identify potential safety hazards, ensuring a safer working environment.

Daily Maintenance Practices

1. Cleaning:

After each use, thoroughly clean your equipment to remove dirt, debris, and crop residues. This prevents blockages and reduces wear and tear on moving parts. Pay special attention to the following areas:

- Air Filters: Clean or replace air filters regularly to ensure optimal engine performance.

- Cooling Systems: Ensure radiators and cooling systems are free from debris to prevent overheating.

2. Lubrication:

Proper lubrication is vital for reducing friction and preventing wear on moving parts. Check and lubricate all grease points daily, including:

- Bearings and Chains: Apply the recommended lubricants to keep these components running smoothly.

- Hydraulic Systems: Ensure hydraulic fluids are at the correct levels and free from contaminants.

3. Inspection:

Perform a visual inspection of your equipment before and after use. Look for signs of wear, damage, or loose parts. Key areas to inspect include:

- Belts and Hoses: Check for cracks, frays, or leaks and replace as necessary.

- Blades and Teeth: Ensure that cutting components are sharp and undamaged.

Seasonal Maintenance Practices

1. Pre-Harvest Inspection:

Before the harvesting season begins, conduct a thorough inspection and servicing of your equipment. This includes:

- Engine Maintenance: Change the oil, replace oil filters, and check spark plugs.

- Hydraulic Systems: Flush and replace hydraulic fluids if needed, and inspect hoses and fittings for leaks or damage.

- Electrical Systems: Check battery health, clean terminals, and ensure all lights and controls are functioning correctly.

2. Post-Harvest Storage:

Properly storing your equipment after the harvesting season is crucial for preventing damage and ensuring it’s ready for the next season. Steps include:

1. Cleaning and Lubrication: Thoroughly clean all parts, lubricate moving components, and apply rust inhibitors to exposed metal parts.

2. Storage Conditions: Store equipment in a dry, sheltered location to protect it from the elements. Use covers or tarps if necessary.

3. Battery Maintenance: Disconnect the battery and store it in a cool, dry place. Consider using a trickle charger to maintain battery health during the off-season.

Troubleshooting Common Issues

1. Engine Problems:

Regularly monitor engine performance and address issues such as hard starting, overheating, or unusual noises promptly. Common causes include:

- Fuel System Issues: Check for clogged fuel filters or airlocks in the fuel lines.

- Spark Plugs: Ensure spark plugs are clean and properly gapped.

2. Hydraulic Failures:

Hydraulic system issues can lead to decreased performance or complete failure. Regularly inspect and address:

- Leaks: Look for fluid leaks around hoses and fittings.

- Pressure: Ensure hydraulic pressure is within the recommended range.

3. Electrical Failures:

Electrical problems can cause a range of issues from minor inconveniences to major breakdowns. Routine checks include:

- Connections: Ensure all electrical connections are secure and free from corrosion.

- Fuses and Relays: Replace any blown fuses or faulty relays.

Maintaining your harvesting equipment is a vital aspect of successful farming. By implementing regular maintenance routines and addressing issues promptly, you can ensure your machinery operates efficiently and reliably throughout the harvesting season. Investing time and resources into proper care and maintenance not only enhances productivity but also extends the lifespan of your equipment, providing long-term benefits for your farming operations. Adhering to these maintenance practices will help you get the best performance out of your harvesting equipment, ensuring that you can meet the demands of each harvest with confidence and efficiency. Get alerts on AgriMag each time a new listing with these specifics is added.

Categories:

Common category

Category Search:

Latest articles:

Top Irrigation Tips for Farmers Facing Water Restrictions

Understanding the Role of Truck Tractors in Logistics

Farming Equipment Upgrades for Small-Scale Farmers in South Africa