Understanding the Different Types of Harvesting Equipment

Date: 17/07/2024

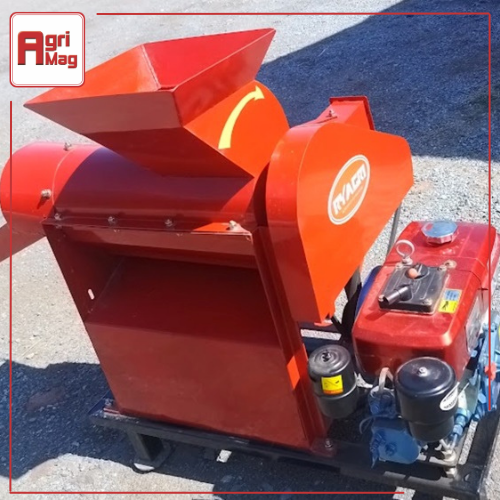

Are you a farmer in the midst of your first harvest and realising that you might be lacking the right equipment? AgriMag understands the importance of having the right tools to maximise your yield and efficiency. Visit our online platform to buy or explore various types of harvesting equipment that suit your specific needs.

Harvesting is a critical phase in the farming process, determining the success and profitability of your efforts throughout the year. In South Africa, where agricultural diversity ranges from grains to cotton and potatoes, having the right harvesting equipment is essential. Let us explore the various harvesting equipment on AgriMag, focusing on their functions and benefits. By understanding these options, farmers can make informed decisions to enhance their productivity and efficiency.

Various Types of Harvesting Equipment

1. Grain Harvesters

Grain harvesters, also known as combines harvesters, are versatile machines used to harvest a variety of grain crops, including wheat, barley, oats, and maize. Combines perform multiple functions, such as cutting the crop, threshing to separate the grain from chaff, and then cleaning the grain. Modern combines are equipped with advanced features like automatic steering, yield mapping, and moisture sensors, which enhance efficiency and reduce losses. These machines are essential for large-scale grain production.

Benefits:

- All-in-One Efficiency: Combines multiple processes into one, saving time and labor.

- High Capacity: Suitable for large-scale grain farming with high throughput rates.

- Quality Preservation: Efficient separation ensures higher quality grain with minimal wastage.

2. Forage Harvesters

These forage harvesters are essential for harvesting crops like maize, alfalfa, and sorghum, which are used primarily for animal feed. These machines cut and chop the forage into small pieces, making it easier to store and use as silage. There are two main types of forage harvesters: pull-type and self-propelled. Pull-type forage harvesters are towed behind a tractor, while self-propelled models are standalone machines. Self-propelled forage harvesters are more powerful and efficient, making them suitable for large-scale operations.

Benefits:

- High Throughput: Can process large volumes of forage quickly, making them ideal for large-scale operations.

- Nutrient Preservation: Chopping and processing forage immediately helps preserve its nutritional value.

- Versatility: Suitable for various forage crops, enhancing utility across different farming activities.

3. Grape Harvesters

These are specialised machines used in vineyards to harvest grapes quickly and efficiently. There are two main types of grape harvesters: mechanical and manual. Mechanical grape harvesters use shaking mechanisms to detach the grapes from the vines, which are then collected in bins. These machines can significantly reduce the labor required for harvesting and are ideal for large vineyards. Manual grape harvesters, although labor-intensive, are preferred for high-quality wine production, as they allow for more careful handling of the grapes.

Benefits:

- Labor Efficiency: Reduces the need for manual picking, lowering labor costs.

- Speed: Quickly collects grapes, essential for timely processing.

- Quality Control: Minimises damage to grapes, preserving their quality for winemaking.

4. Potato Harvesters

These harvesters are designed to lift potatoes out of the soil while minimising damage to the tubers. They use a series of blades or diggers to loosen the soil and lift the potatoes onto a conveyor system, which then separates the potatoes from the soil and other debris. There are two main types of potato harvesters: single-row and multi-row. Single-row harvesters are suitable for smaller farms, while multi-row harvesters can handle larger fields more efficiently.

Benefits:

- Save on Labour: Automated harvesting significantly reduces manual labor.

- Minimised Crop Damage: Gentle handling reduces damage to potatoes, improving marketability.

- Increased Productivity: Faster harvesting allows for timely collection, reducing crop losses.

5. Cotton Harvesters

Cotton is another significant crop type in South Africa, requiring specialised equipment for harvesting. There are two primary types of cotton harvesters: spindle pickers and strippers. Spindle pickers use rotating spindles to pick the cotton from the bolls without damaging the plant, making them ideal for high-quality cotton. Strippers, on the other hand, remove the entire boll from the plant, including the cotton and any debris. While strippers are faster, they may require additional processing to separate the cotton from the debris.

Benefits:

- Reduced Labor Costs: Mechanised harvesting is faster and requires fewer laborers.

- Improved Cotton Quality: Pickers minimise damage to cotton fibers, maintaining quality.

- Higher Yields: Efficient harvesting increases the amount of cotton collected.

6. Sugar Cane Harvesters

Sugar cane is a vital crop in South Africa, requiring specialised equipment for efficient harvesting. Sugar cane harvesters are designed to cut the cane stalks at the base, strip the leaves, and chop the stalks into manageable lengths. Modern sugar cane harvesters are equipped with advanced technology such as GPS and sensors to optimise harvesting patterns and reduce waste. These machines can handle the tough and fibrous nature of sugar cane, ensuring that the harvest is quick and efficient.

Benefits:

- Increased Efficiency: Automated cutting and collecting significantly reduce labor costs and time.

- Consistent Quality: Uniform cutting ensures better quality and easier processing of sugar cane.

- Enhanced Safety: Reduces the physical strain and risk of injuries to workers.

7. Peanut Harvesters

These are the types of harvesting equipment designed to dig up peanut plants, shake off the soil, and separate the peanuts from the vines. These machines typically have a digger blade that loosens the soil around the peanut plants and lifts them onto a conveyor. The peanuts are then separated from the vines and collected in a hopper or trailer. Peanut harvesters come in various sizes, from small, single-row models to larger, multi-row machines suitable for extensive peanut farms.

Benefits:

- Efficiency: Streamlines the harvesting process, reducing manual labor.

- Quality Maintenance: Minimises damage to peanuts, ensuring better quality.

- Time-Saving: Fast harvesting allows timely collection, reducing the risk of crop spoilage.

Understanding the different types of harvesting equipment is crucial for farmers aiming to maximise their yield and efficiency. From sugar cane and forage harvesters to specialised machines for cotton, potatoes, grains, peanuts, and grapes, each type of equipment offers unique benefits tailored to specific crops. To explore and invest in the right kind, find harvesting equipment to ensure a more productive and profitable harvest season.

Read Related Articles

Categories:

Common category

Category Search:

Latest articles:

What to Look for When Buying a Skidsteer Loader for Farming

Why Planning Early for the Planting Season Pays Off

Why Winter Feed Management is Crucial for Livestock Health