Exploring the Types of Borehole Equipment in South Africa

Date: 05/09/2022

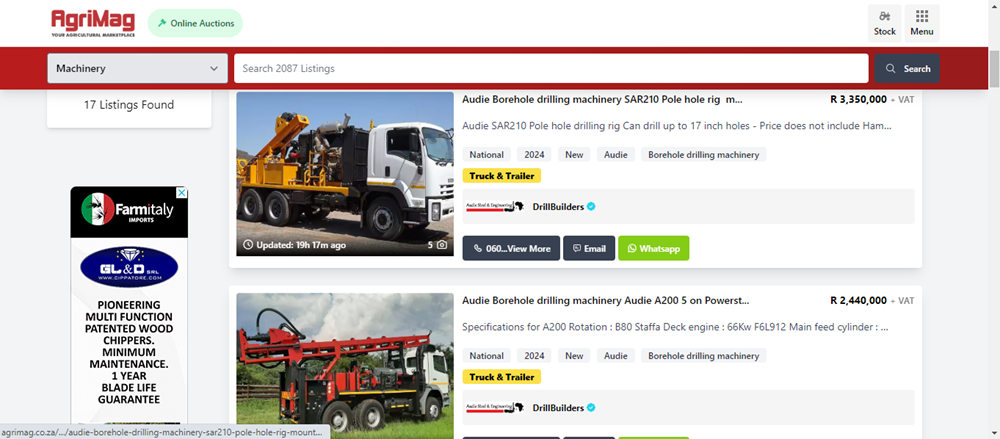

There are different types of borehole drilling machinery employed across South Africa to tackle various drilling needs in agriculture, mining, and water management. This machinery is crucial for extracting underground resources efficiently. Understanding these machines' capabilities and specific uses helps in selecting the right equipment for any drilling project. Find borehole farming equipment for sale on AgriMag and launch your new drilling business today.

The Significance of Borehole Drilling Equipment

Borehole drilling is essential in South Africa due to the country's need for accessing natural underground resources, such as water, minerals, and geothermal energy. The types of machinery used for these purposes vary greatly, depending on the depth, soil composition, and the specific resource being targeted.

Main Types of Borehole Drilling Machinery

1. Rotary Drills

Rotary drills are among the most common types of borehole drilling machinery. They work by rotating a drill bit at the end of a drill pipe, which cuts through the earth. These drills are particularly effective in softer ground conditions and are widely used in water borehole drilling and for mineral exploration. There are two primary types:

- Direct Rotary Drills: Utilise a fluid (usually water or mud) to bring cuttings up to the surface.

- Reverse Circulation Rotary Drills: Where the cuttings are forced up the annulus by compressed air, making them suitable for deeper and larger-diameter boreholes.

2. Down-the-Hole Hammer Drills (DTH)

DTH drills are ideal for hard rock formations and are commonly used in mining and quarrying. These machines operate by hammering a drill bit into the rock while it rotates, fracturing the rock into smaller pieces and enabling deeper penetration. They are efficient in producing clean, straight boreholes with diameters ranging from about 90 mm to 300 mm.

3. Cable Tool Drills

Cable tool drilling, also known as percussion drilling, is one of the oldest methods of drilling. It involves lifting and dropping a heavy cutting tool into the borehole to crush and pulverise the rock. Although slower compared to rotary and DTH methods, cable tool drills are cost-effective for shallow water well drilling and are less dependent on complex machinery.

4. Auger Drills

Used predominantly for soil sampling and shallow drilling, auger drills are suitable for soft ground conditions such as clay, sand, or loam. These drills operate by rotating a helical screw blade to lift soil cuttings up out of the hole. They are commonly used for environmental testing and construction projects.

5. Core Drills

Core drilling is used when precise circular cores are needed from the earth. It is particularly crucial in mineral exploration to obtain sample cores for analysis. These drills use a diamond-tipped drill bit to cut a core of rock, which is then extracted in cylindrical sections for study.

Selecting the Right Drilling Machinery

Choosing the appropriate type of borehole drilling machinery depends on several factors:

- Purpose of the drill: Differentiating whether it's for water extraction, mineral exploration, or environmental sampling can dictate the choice of drill.

- Depth and diameter of the borehole: Deeper or wider boreholes may require more robust drilling systems like rotary or DTH drills.

- Type of terrain: Soil and rock compositions significantly influence the choice of drilling method.

Why It's Important to Buy Borehole Drilling Machinery on AgriMag

When it comes to purchasing borehole drilling equipment, selecting the right platform can be just as crucial as choosing the right equipment. AgriMag, a leading online marketplace in South Africa, offers a comprehensive and reliable solution for sourcing drilling machinery. Here are several reasons why AgriMag stands out as the preferred choice for buying borehole drilling machinery:

1. Wide Range of Options

AgriMag provides access to a diverse array of borehole drilling equipment, catering to different drilling needs and preferences. Whether you’re looking for rotary drills, DTH hammers, auger drills, or any other type, you can find various models and configurations. This variety ensures that buyers can compare different types of machinery and select the one that best fits their project requirements.

2. User-Friendly Interface

AgriMag’s platform is designed with user experience in mind, making it easy for buyers to search and filter through listings. This user-friendly interface simplifies the process of finding the right borehole drilling machinery by allowing users to sort by type, price, location, and more. This accessibility helps save time and effort in the procurement process.

3. Competitive Pricing

Because AgriMag hosts a wide range of sellers, it fosters a competitive marketplace where buyers can benefit from competitive pricing.

Understanding the types of borehole drilling machinery available in South Africa is essential for tackling the diverse drilling needs presented by its varied geography and resource distribution. Each type of drill offers unique benefits and is suited to specific conditions and purposes. Whether for extracting water, sampling the environment, or mining minerals, the right drilling machinery is key to achieving efficient and effective results. Start your search to find borehole farming equipment for sale on AgriMag and launch your drilling business today.

Categories:

Common category

Category Search:

Latest articles:

Why Planning Early for the Planting Season Pays Off

Why Winter Feed Management is Crucial for Livestock Health

How Smart Farming Technology is Revolutionising Agriculture