Exploring and Understanding the Different Types of Compressors

Date: 05/12/2023

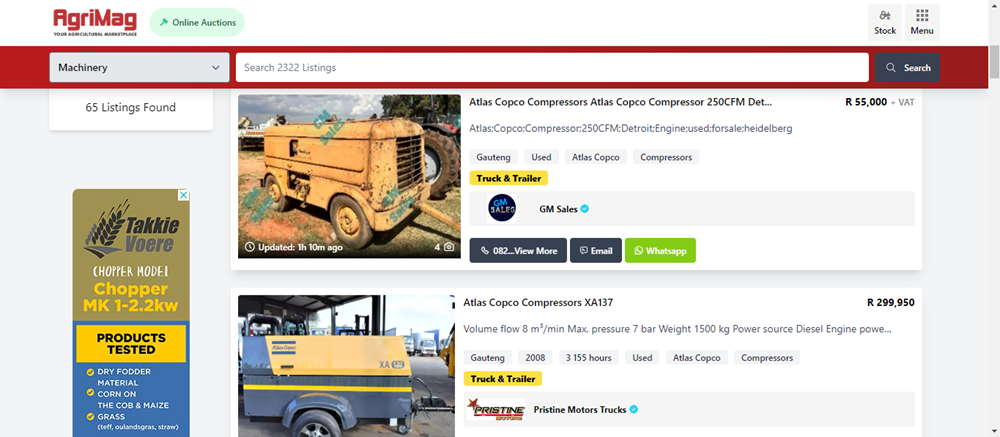

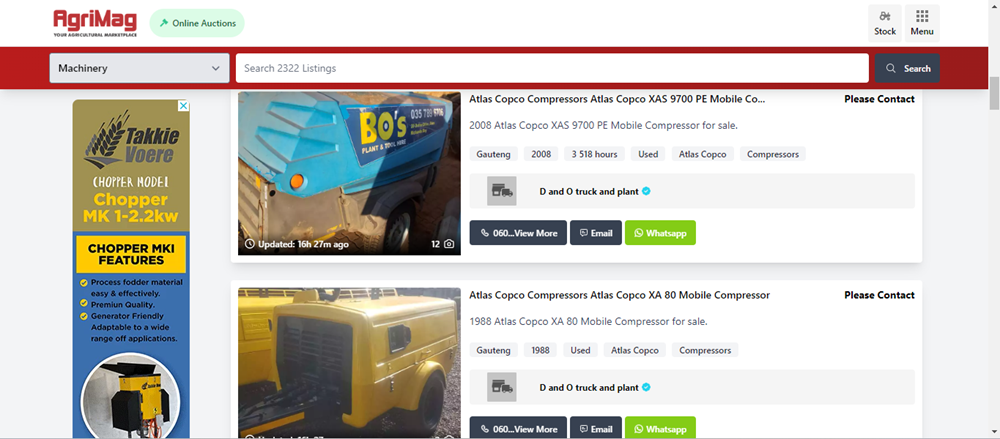

Are you in the market for a compressor but overwhelmed by the array of options available? Choosing the right type of compressor can greatly impact your operations, whether for industrial use or household applications. Understanding the different types and their functionalities is crucial in making an informed decision. Join us as we delve into the world of these machines and explore the various types suited for diverse needs in the industry. Buy machinery for sale on AgriMag at affordable prices.

Types of Compressors

Reciprocating Compressors:

They operate through the principle of reciprocating motion, where a piston compresses air within a cylinder. These compressors are commonly used in applications requiring high pressure, such as automotive workshops, small manufacturing plants, and refrigeration systems. They are available in both lubricated and oil-free variants, offering flexibility based on specific requirements.

Rotary Screw Compressors:

These compressors utilise two interlocking helical rotors to compress air. They are renowned for their efficiency, reliability, and quiet operation, making them ideal for continuous-duty applications. They find extensive use in industries like construction, automotive, and pharmaceuticals, providing a steady supply of compressed air for various tools and processes.

Centrifugal Compressors:

These one rely on the centrifugal force generated by a rotating impeller to compress air. With their ability to handle large volumes of air at high speeds, they are often employed in demanding industrial settings, including power generation plants, chemical processing facilities, and oil refineries. Centrifugal compressors excel in applications requiring continuous, high-volume airflow.

Scroll Compressors:

With these type of compressors feature two interleaving spiral-shaped scrolls, where one remains stationary while the other orbits around it. They are valued for their compact design, quiet operation, and energy efficiency. They are commonly found in air conditioning systems, refrigeration units, and heat pumps, providing reliable performance in both residential and commercial settings.

Axial Compressors:

These compressors operate by accelerating air in a linear direction through rows of rotating and stationary blades. They are predominantly utilised in large-scale industrial processes, such as gas turbines, jet engines, and aircraft propulsion systems. Axial compressors are renowned for their high efficiency and ability to handle large volumes of airflow at relatively low pressures.

Comparing Compressor Types for Specific Applications

Understanding the different types of compressors and their unique attributes can help you make a more informed choice for specific applications.

1. Industrial Applications:

For heavy industrial applications, the durability and efficiency of rotary screw compressors often make them the preferred choice. Industries like mining, construction, and large-scale manufacturing rely heavily on these compressors due to their ability to provide a continuous, reliable supply of compressed air. Centrifugal compressors also play a crucial role in industrial settings, particularly in large plants where significant volumes of air are required consistently.

2. Automotive Industry:

In the automotive sector, reciprocating compressors are commonly used in workshops and garages for tasks such as tire inflation, pneumatic tools, and spray painting. Their ability to deliver high-pressure air in short bursts makes them ideal for these applications. However, for larger operations requiring more sustained air pressure, rotary screw compressors might be more efficient.

3. HVAC Systems:

For heating, ventilation, and air conditioning (HVAC) systems, scroll compressors are often the go-to option. Their compact size and quiet operation make them perfect for residential and commercial environments where space and noise levels are considerations. Additionally, their energy efficiency helps reduce operational costs, a significant advantage for both homeowners and businesses.

4. Refrigeration:

In refrigeration systems, both reciprocating and scroll compressors are widely used. Reciprocating compressors are suitable for commercial refrigeration due to their ability to handle variable loads effectively. On the other hand, scroll compressors, known for their reliability and low noise, are commonly found in residential and smaller commercial refrigeration units.

5. Aerospace and High-Tech Industries:

Axial compressors are predominantly used in aerospace applications, such as jet engines and gas turbines, due to their ability to handle large volumes of air at high speeds and relatively low pressures. These compressors are essential in environments where high efficiency and performance are critical, supporting the stringent demands of high-tech industries and advanced engineering applications.

Energy Efficiency and Environmental Impact

With the growing emphasis on energy efficiency and sustainability, the choice of compressor also impacts environmental considerations. Rotary screw and scroll compressors are particularly noted for their energy-efficient operation. Choosing energy-efficient compressors not only reduces operational costs but also minimizes the carbon footprint, aligning with global efforts to combat climate change.

Maintenance and Longevity

Another critical factor to consider is the maintenance and longevity of compressors. Reciprocating compressors typically require more frequent maintenance due to the wear and tear of moving parts. Conversely, rotary screw compressors, known for their robust design, often have longer service intervals and lower maintenance requirements, making them a cost-effective choice in the long run.

Future Trends in Compressor Technology

The compressor industry is continually evolving, with advancements aimed at improving efficiency, reducing noise levels, and enhancing performance. Innovations such as variable speed drive (VSD) technology allow compressors to adjust their output to match the demand, leading to significant energy savings. Additionally, the development of oil-free compressors is gaining traction, especially in industries where air purity is critical, such as pharmaceuticals and food processing.

By understanding the right types of compressors available in the market caters to various needs across different industries and applications. Whether you require high-pressure output, continuous-duty operation, or energy-efficient performance, there's a compressor type suited to meet your requirements. Understanding the functionalities and advantages of each type is essential in selecting the right compressor for your specific needs. So, whether it's for industrial operations, automotive maintenance, or residential HVAC systems, knowing the types of these machines available empowers you to make informed decisions and optimise performance. Get machinery for sale on AgriMag at affordable prices.

Categories:

Common category

Category Search:

Latest articles:

What to Look for When Buying a Skidsteer Loader for Farming

Why Planning Early for the Planting Season Pays Off

Why Winter Feed Management is Crucial for Livestock Health