Choosing the Right Roller for Your Project: A Guide for the Market

Date: 11/10/2023

Are you struggling with choosing the right roller for your project? Whether you are working on a small home garden or a large agricultural field, the right roller can significantly impact your project's success. In this guide, we will explore the various types of rollers available, their uses, and how to choose the best one for your specific needs. Stay with us as we delve into everything you need to know about selecting the perfect roller. Visit AgriMag for the best range of rollers and other advice. To ensure that your projects go easily and effectively, we are here to assist you in selecting the ideal roller for your requirements.

Understanding Rollers and Their Importance

Rollers are essential tools in agriculture, landscaping, and construction. They are used to compact soil, gravel, concrete, or asphalt, creating a smooth, even surface. This compaction is crucial for preparing land for planting, improving soil structure, and ensuring stable foundations for construction projects.

Types of Rollers

Smooth-Wheeled Rollers

- Usage: Ideal for granular soils like sand, gravel, and crushed stone.

- Benefits: Provides a smooth finish and is excellent for road construction and large-scale agricultural fields.

- Considerations: Not suitable for cohesive soils like clay.

Pneumatic Tyred Rollers

- Usage: Suitable for compacting fine-grained soils and asphalt.

- Benefits: Flexible tires provide uniform pressure, making them effective on uneven surfaces.

- Considerations: Requires regular maintenance of the tyres for optimal performance.

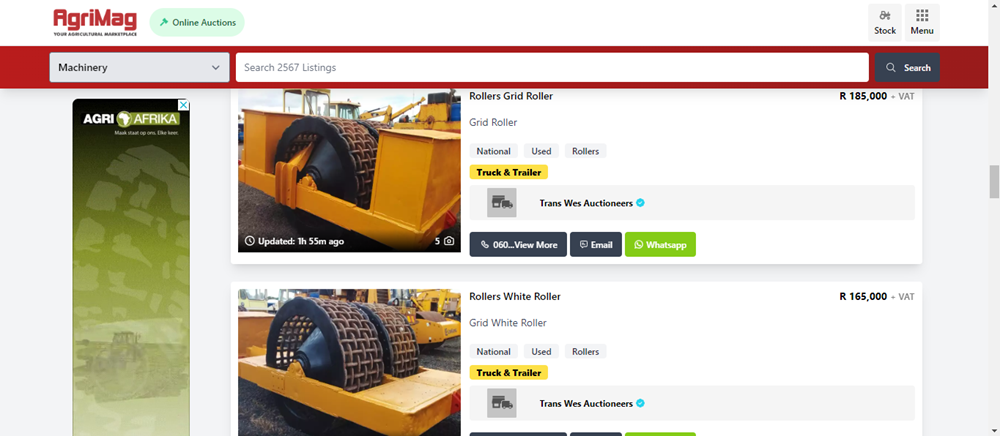

Sheepsfoot Rollers

- Usage: Best for compacting cohesive soils such as clay and silty clay.

- Benefits: The protruding "feet" penetrate the soil, providing deep compaction.

- Considerations: Not suitable for granular soils as it can lead to over-compaction.

Padfoot Rollers

- Usage: Similar to sheepsfoot rollers, but with larger, flatter pads.

- Benefits: Ideal for compacting cohesive soils and landfill sites.

- Considerations: Less effective on granular soils.

Vibratory Rollers

- Usage: Can be used on both granular and cohesive soils.

- Benefits: The vibrating motion helps achieve deeper compaction with less effort.

- Considerations: More expensive and requires careful handling to avoid over-compaction.

Key Factors to Consider When Choosing a Roller

Soil Type

Understanding the type of soil you are working with is crucial. For example, smooth-wheeled rollers are perfect for sandy soils, while sheepsfoot rollers are better for clay.

Project Size

Larger projects may require more robust and efficient rollers like vibratory or pneumatic tyred rollers. Smaller projects can often be managed with lighter, less complex rollers.

Budget

These machines vary significantly in price. It is important to balance your budget with the requirements of your project. Investing in a high-quality roller can save money in the long run by reducing maintenance and improving efficiency.

Terrain

Consider the terrain where the roller will be used. Uneven or hilly terrains may benefit from pneumatic tyred rollers, which provide better traction and adaptability.

Frequency of Use

For frequent use, investing in a durable, high-quality roller is advisable. For occasional projects, a less expensive, simpler model may suffice.

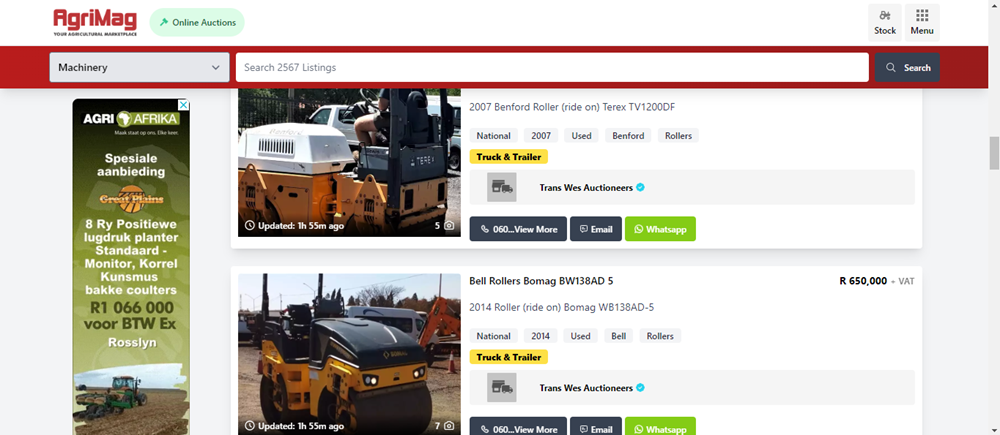

Popular Brands and Models in South Africa

Known for their durability and efficiency, Bomag offers a range of rollers suitable for various applications.

Popular for their innovative design and robust performance, Dynapac rollers are widely used in construction and agriculture.

Caterpillar is a trusted name in heavy machinery, offering reliable and powerful rollers for large-scale projects.

This brand provides high-quality rollers designed to withstand the local conditions and requirements.

Tips for Maintaining Your Roller

Regular Inspections

Regularly check for wear and tear, and address any issues immediately to avoid costly repairs.

Proper Lubrication

Ensure all moving parts are well-lubricated to maintain smooth operation and extend the roller's lifespan.

Clean After Use

Cleaning your roller after each use prevents the buildup of dirt and debris, which can cause damage over time.

Store Correctly

Store your roller in a dry, sheltered area to protect it from the elements and reduce the risk of rust and corrosion.

Choosing the right roller for your project is essential for achieving the best results. By understanding the different types of rollers and their specific uses, you can make an informed decision that will save time and money while ensuring the success of your project. For more tips and the best selection of rollers, visit AgriMag. We are here to help you choose the perfect roller for your needs, ensuring your projects run smoothly and efficiently.

Read Related Articles

Categories:

Common category

Category Search:

Latest articles:

What to Look for When Buying a Skidsteer Loader for Farming

Why Planning Early for the Planting Season Pays Off

Why Winter Feed Management is Crucial for Livestock Health